As technologies advance and demand for semiconductors grows, KLA’s technical training and development program innovates to keep pace and prepare service teams to deliver exceptional ownership experiences for KLA customers.

Whether customers have leading-edge or mature equipment, service employees train intensely with KLA’s Learning and Knowledge Services (LKS) organization, preparing them to resolve issues quickly and efficiently. Customer service engineers (CSEs), technical service engineers (TSEs) and installers new to KLA, for example, begin up to 12 weeks of onsite and hands-on product-focused training as soon as they get their laptops, and veteran service employees stay up to date with LKS coursework as part of their ongoing development.

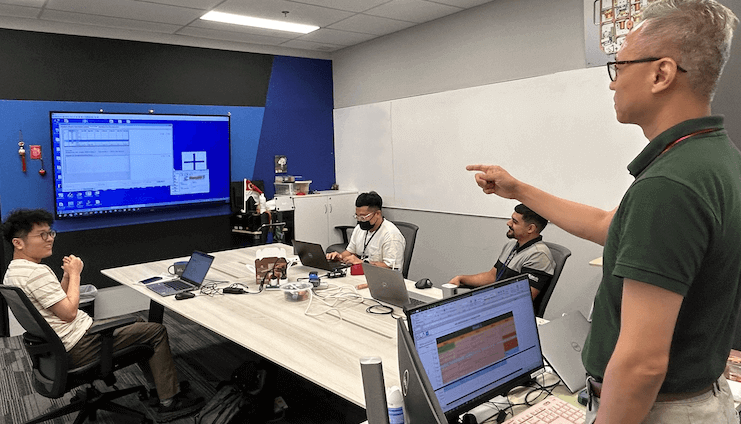

Both virtually and at LKS locations globally they learn how to operate, troubleshoot, repair and maintain the tools in use at customer locations. Which, with such high-precision instruments, requires far more advanced service expertise, and LKS has evolved its training programs accordingly.

Staying Ahead of Evolving Technologies and New Product Introductions

“Next-gen tools continue to get more complex. LKS has to engineer curriculums and certifications for our technical workforce so they are able to support the tool availability and performance our customers expect.”

Efren Lopez, senior director, KLA Learning and Knowledge Services

To keep up with the increasing complexity of KLA tools and customer needs, the LKS organization has developed innovative instruction methods, starting as part of the standard product lifecycle process. Because some products have lifecycles spanning 30 years or more, LKS must continuously evolve the curriculums to include new and older tools that might be upgraded.

During new product introductions, LKS instructors work closely with KLA’s engineering and product support teams to define a training strategy and develop required training and certifications to support product capabilities and availability. Instructors also receive training so they are deemed proficient and able to more effectively design and teach the courses, and LKS also trains KLA employees in engineering, applications, manufacturing and other technical organizations.

KLA has more than 200 types of products serving unique customer requirements. Tools can have more than 16,000 parts and over 300 field-replaceable units. KLA’s 3,000-plus CSEs rely on LKS to help them optimize tools so they operate at each customer’s specification.

From the Field

Eddie Miller, a CSE in Oregon who has worked at KLA for 22 years, helps his customer sustain a high rate of quality and throughput.

“KLA’s tools are very complex, and I train to keep up with the customer demands and technology changes within our industry,” he says.

But it’s not only new and emerging products that are on customers’ production floors. Of approximately 50,000 KLA tools installed around the world, more than half are over 18 years old, which speaks to the enduring value of the products.

“KLA builds products that last a long time,” Efren explains, “so LKS always considers the breadth of our entire portfolio to keep new and longtime CSEs up to speed on older tools still in use.”

Hands-on Training from Qualified Experts

Whether new employees or longer-service team members, KLA’s CSEs and installers already have engineering or technical backgrounds. After months of online coursework, they spend time at an LKS location for hands-on interaction with KLA tools.

In an upcoming posting, read how LKS is teaching with augmented reality – or AR – and how KLA employees are using emerging technologies to support customers. To be part of the next technological breakthrough, consider a career at KLA. Browse job openings at multiple global locations.

Follow Us