In the biomedical industry, many different types of devices such as sensors, monitors, prosthetics, drug delivery systems and implants are used both inside and outside the human body.

“KLA Instruments has a growing portfolio of optical and stylus profilers, thin-film measurement systems and nanoindenters to help the medical design community increase yield and time-to-market. Whether measuring the roughness of a surface, determining the thickness of a coating, profiling the surface properties of a new material or conducting nanomechanical testing, we offer multiple metrology solutions to biomedical industry manufacturers.”

Manjit Daniel, senior director, worldwide sales, KLA Instruments

Thin Film Coatings Offer Patient Protection

Thin film coatings such as transparent parylene often protect a medical device or a part from corrosion, while other biocompatible coatings protect the patients from unfortunate complications such as tissue trauma, infection or even bodily rejection. Some devices, including angioplasty balloons, are freestanding membranes that must be of uniform and fixed thickness to function properly.

Due to its superior coating properties, the range of parylene applications has expanded from coating extreme-service printed circuit boards (PCBs) to include a wide array of industrial electronic uses, including biomedical. The parylene coating process is formed from a gaseous phase with an intermediate liquid stage, resulting in conformal coatings that cover sharp edges, points, crevices and exposed internal surfaces with a uniform thickness and with an absence of pinholes. This thin film coating is an effective barrier layer because it is highly reliable, lightweight, stress-free, transparent and biocompatible.

Methods for measuring coating thickness can vary, but measuring monitor samples instead of the actual parts often misses coating flaws. Measuring the weight of a part before and after coating may yield an average thickness value but will miss local flaws or nonuniformities that can cause failure with serious implications.

Metrology Solutions for the Biomedical Industry from KLA Instruments

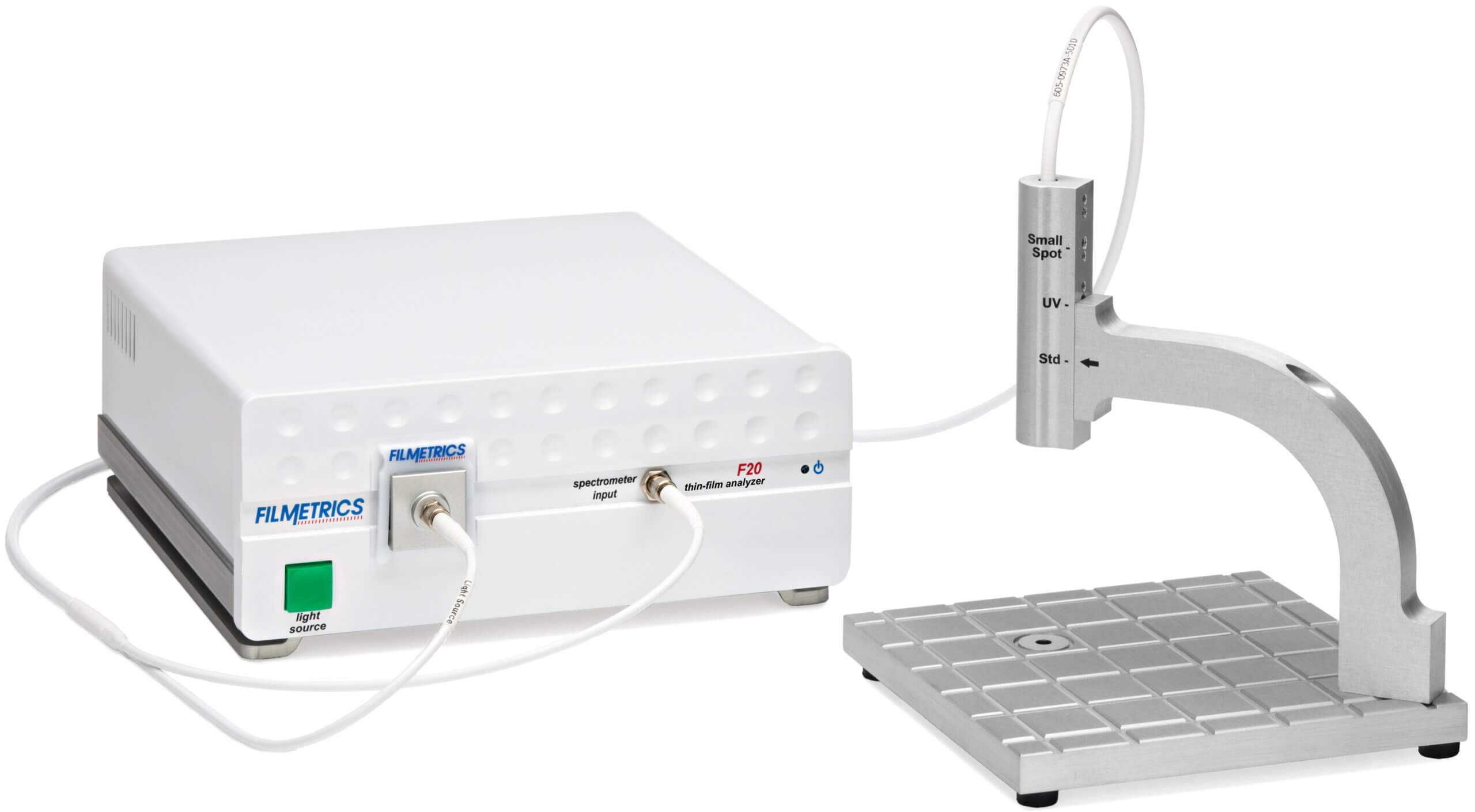

Filmetrics® metrology tools measure film and coating thickness using spectral reflectance, where light is reflected off the sample and then analyzed over a range of wavelengths. Light reflected from the top and bottom interfaces of the film can be in-phase so that reflections add, or out-of-phase so that reflections subtract. The result is characteristic intensity oscillations in the reflectance spectrum.

Simply put, the thicker the film, the more oscillations will be present in the reflectance spectrum. The Filmetrics F20, F40, and F3-CS thin-film analyzer systems are recommended for precise thickness measurement of coatings on biomedical devices including:

- Stents

- Medical and Orthopedic Implants

- Guide wires, needles

- Catheter and angioplasty balloon wall thickness

- Ophthalmics

Filmetrics F20

Filmetrics F20 systems are general-purpose film thickness measurement instruments that are used in thousands of applications globally.

Thickness and refractive index can be measured in less than a second. Like all Filmetrics thickness measurement instruments, the F20 connects to your computer’s USB port and sets up in minutes.

The different Filmetrics F-series instruments and their configurations are distinguished primarily by the film thickness measurement range, which in turn is determined by the instrument’s wavelength range. Learn more about the differences in the Parylene Coatings application note in the Thin Film Reflectometers section of our technical literature page.

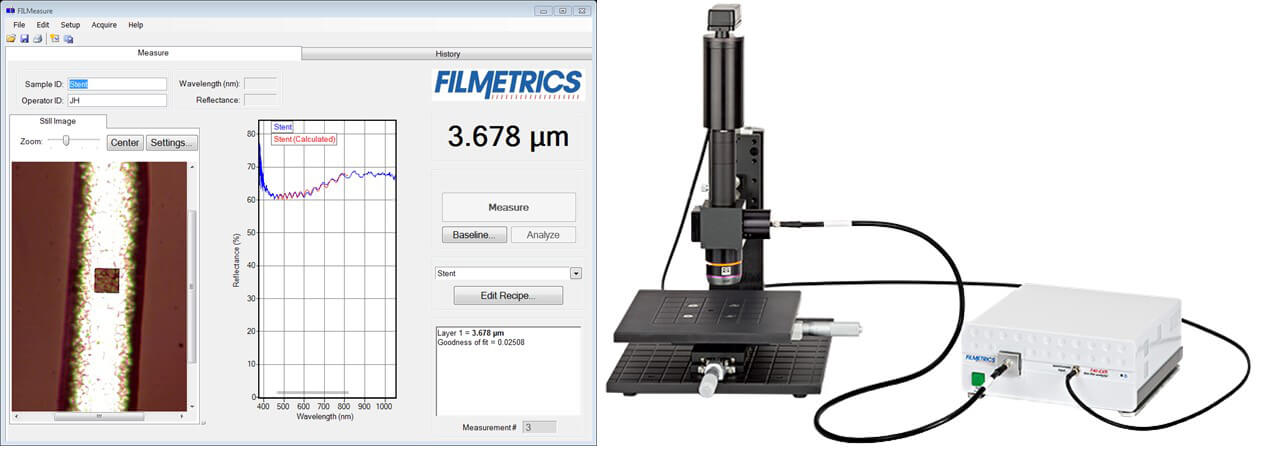

Filmetrics 40

The F40 product family is for applications that require a spot size as small as 1μm. For most microscopes, the F40 simply attaches to the C-mount adapter, which is the industry standard for video camera mounting.

The F40 thickness measurement instrument comes complete with an integrated color video camera that allows exact monitoring of the film thickness measurement spot. Thickness and index can be measured in less than 1s. Like all our tabletop film thickness measurement instruments, the F40 connects to your computer’s USB port and sets up in minutes.

“Controlling balloon wall thickness with the Filmetrics F40 on dilation balloons allows our customers to deliver high quality, reliable dilation balloons for their patients,” says Menno Bouman, applications manager, KLA Instruments.

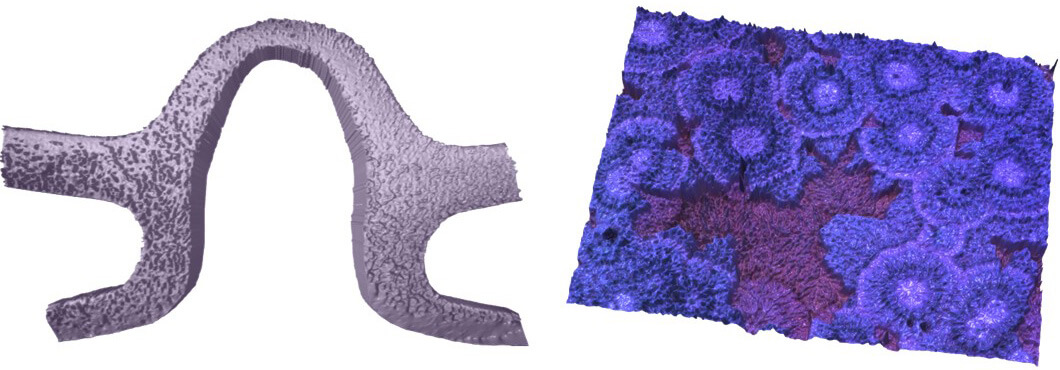

Filmetrics Profilm3D®

In addition to film and coating thickness measurement systems, the Profilm3D® optical profiler generates 3D measurements of surface topography, roughness, step height and many other surface features of interest for biomedical devices.

TotalFocus® 3D imaging optimizes the focus for each pixel through the full vertical range.

True-color imaging delivers the actual colors for enhanced visualization, especially for subtle or buried features, and enhanced roughness mode (ERM) delivers improved fidelity for highly sloped surfaces such as lenses.

Follow Us